Efficiency is the key to any business’s success in this competitive landscape, and the bottled water industry is no exception. Water manufacturing plays a crucial role in the increase in demand for clean and healthy water. Businesses are turning to innovative solutions like bottled water manufacturing software to fulfill customer demand and strive to thrive in the competition.

Are you striving to manage your bottled water manufacturing processes efficiently? If yes, this blog is for you.

Bottled water manufacturing software is a comprehensive tool that automates and optimizes your business operations from processing to delivering.

This blog will explore everything about this manufacturing software and how it can help you manage your business.

What is bottled water manufacturing software?

Bottled water manufacturing software is an enterprise resource planning solution that automates and streamlines business processes. It includes a comprehensive suite of business application modules specifically designed to manage bottled water production.

The bottled water manufacturing process includes:

- Tracking raw materials

- Managing production lines

- Quality control

- Delivery logistics

- Sales orders

- Inventory management

Inventory management is one of the essential processes for optimal bottled water production while ensuring high-quality water and complying with regulations. It enables lot tracking that makes product recalls easy and quick in case of quality issues. The bottled water manufacturing inventory management software includes:

- Regulatory compliance

- Multi-level approval workflow

- Quality control

- Lot tracking

- Packaging

- Recipe management

Why does your business need bottled water manufacturing ERP?

High demand and quality water have led to increased bottled water production. Managing a complex water supply chain is difficult without a dedicated bottled water manufacturing ERP. If you are managing your bottled water operations manually and not using a centralized system, you might be facing these challenges:

Inefficient production management

Manual production planning, scheduling, and tracking are inefficient. Monitoring production progress, identifying problems, and responding quickly to changing demands becomes more difficult. Tracking quality metrics to ensure compliance with regulations. This results in:

- Errors, delays, and inconsistencies

- Production inefficiencies and missed deadlines

- Lowered product quality and costly recalls

Inventory management issues

Managing inventory manually is time and effort-consuming and prone to errors. The inability to get real-time visibility into raw material levels makes tracking finished goods difficult. Ineffective inventory management can result in:

- Stockouts and overstocking

- Delayed procurement and production delays

- Late order fulfillment and customer dissatisfaction

Sales and distribution challenges

Manual order processing and customer query handling are difficult without a centralized system. Managing route planning manually is prone to errors, leading to missed deliveries. Real-time shipping tracking is impossible. Handling returns manually can be ineffective. These sales and distribution challenges can lead to:

- Slow order processing and delivery delays

- Increased delivery costs

- Customer disputes and dissatisfaction

Discrepancies in financial management

Manual finance management can be inaccurate and time-consuming. Invoicing or billing are prone to errors and lead to reworks. Reconciling payments manually can be a tedious and time-consuming task. Inefficient financial management can result in:

- Discrepancies in payables and receivables

- Poor cash flow and financial instability

- No financial reporting

Limited data visibility

You can not track key performance indicators without a centralized system. Manually generating such reports is time-consuming and prone to errors. Without access to real-time data visibility, you might find:

- Identifying areas for improvement is difficult

- Making data-driven decisions

- Inability to analyze data and identify trends

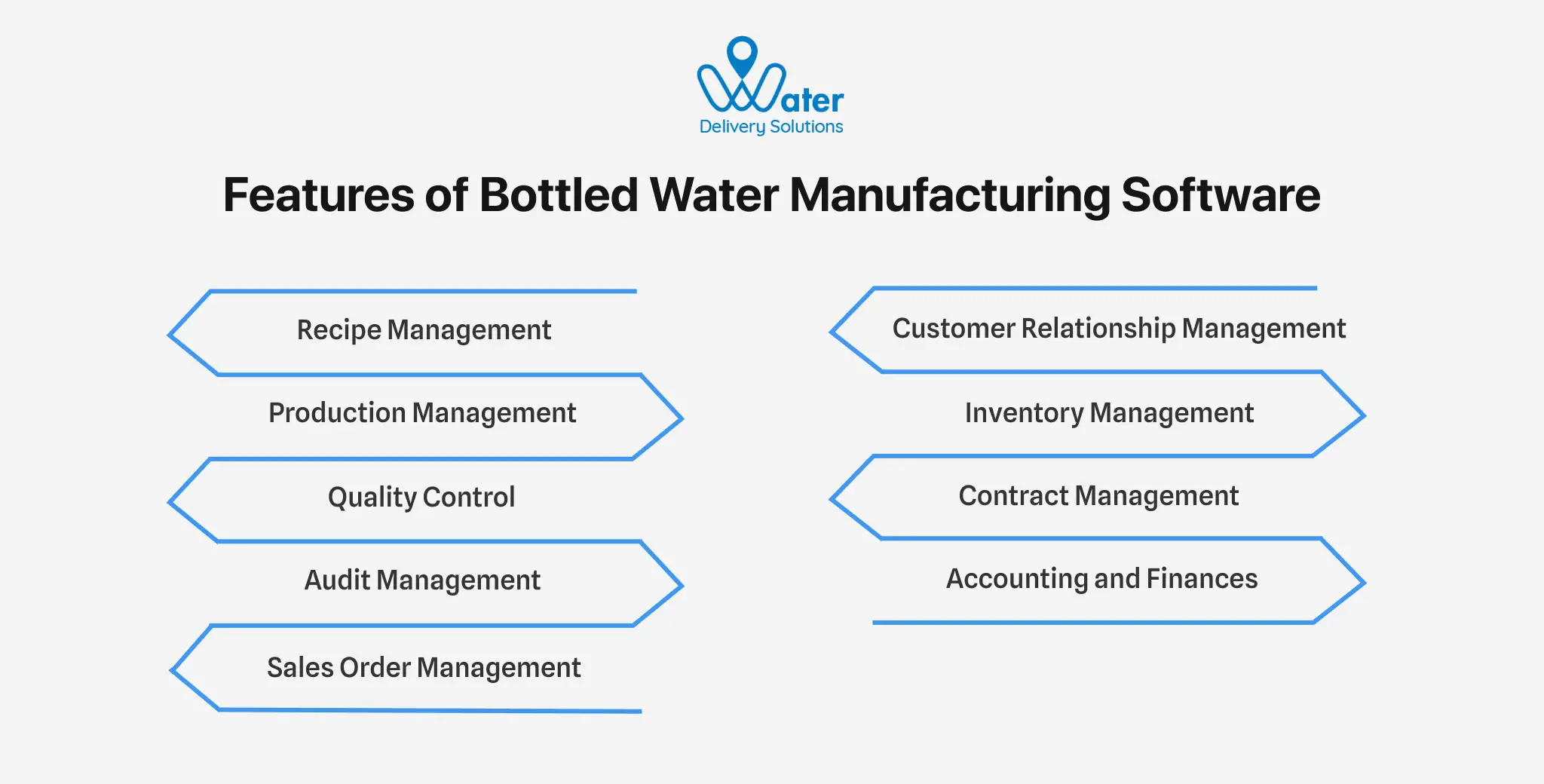

Features of bottled water manufacturing software

Water Delivery Solutions offers manufacturing software with advanced features to optimize and streamline the bottled water manufacturing process, improving efficiency and reducing operational costs. The features of bottled water manufacturing software are:

Recipe management

This feature of the manufacturing ERP system allows you to manage and track the inventory of the formulas for different water products, including mineral content, flavoring, etc. It ensures standard production and helps you control ingredient costs.

Production management

This process consists of production planning, scheduling, execution, and tracking. The system helps you optimize production runs, manage resources, and monitor productivity. This can help reduce downtime and manage maintenance schedules.

Quality control

It is crucial for any consumable product, including bottled water. It ensures that you meet regulatory requirements and customer satisfaction. This feature allows you to manage quality checks at various production stages, track test results, and generate quality reports.

Audit management

It streamlines preparing for and conducting audit processing, enabling industrial compliance. You can manage documentation, schedule audits, and track audit findings.

Sales order management

You can manage and track sales orders from order entry to fulfillment. This process includes order tracking, invoicing, and shipping documentation. You must integrate an inventory module to ensure seamless order fulfillment and customer satisfaction.

Customer relationship management

The CRM module helps you manage customer interactions, track their preferences, and improve customer service. Efficient customer management includes contact management, sales history, and customer communication tools.

Inventory management

The system allows you to track raw materials (bottles, caps, labels, and water), packaging materials, and finished goods. Real-time inventory tracking helps optimize inventory levels to prevent stockouts and minimize waste. The system also enables you to handle lot tracking and traceability.

Contract management

The ERP bottled water manufacturing system allows you to manage contracts with suppliers, distributors, and customers. Contract management includes creating, tracking, and renewing the contract.

Accounting and finances

Integrating accounting and finance modules is essential for managing financial transactions, tracking costs, and generating financial reports. This includes accounts payable, accounts receivable, general ledger, and cost accounting.

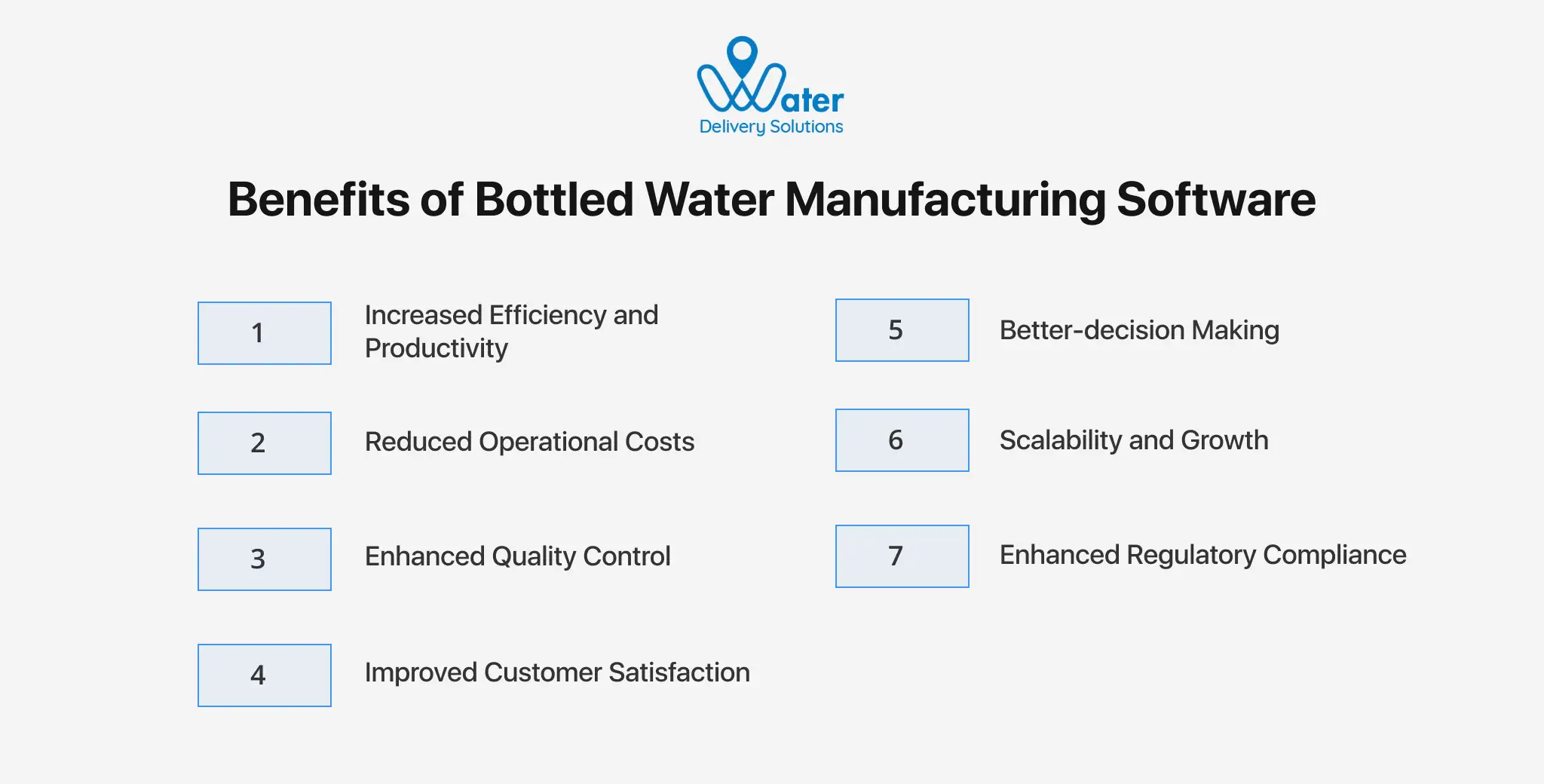

Benefits of bottled water manufacturing software

It offers robust and advanced features to streamline your production with other major operations while cutting operational costs and improving profits. The benefits water manufacturing software offers are:

Increased efficiency and productivity

Automating manual operations can free up valuable time and resources. Optimizing production planning, scheduling, and execution can help you reduce production issues and improve efficiency. Real-time insights allow for quickly identifying pain areas and making faster decisions. Optimized resource allocation can help you reduce waste and costs.

Reduced operational costs

Optimizing inventory can lower storage costs and reduce waste. The system can help you improve production efficiency, reduce downtime, and minimize material waste. Delivery route optimization can reduce fuel consumption and transportation expenses. Automating administration tasks minimizes the need for manual data entry and paperwork, mitigating errors and reworks.

Enhanced quality control

Tracking quality metrics and recipes and implementing quality control measures ensure consistent product quality. The system allows you to trace products and enable quick identifications and recalls in case of quality issues.

Improved customer satisfaction

Efficient customer relationship management enhances communication among the stakeholders. It streamlines order processing and delivery to ensure timely deliveries and customer satisfaction.

Better-decision making

The ERP solution provides real-time data and analytics, enabling you to make informed decisions. It considers historical data and trends to forecast demand and help in business and inventory planning. The system tracks key performance indicators of your business to identify the areas for improvement and measure progress.

Scalability and growth

The manufacturing enterprise resource planning system is a scalable platform that can accommodate increasing production volumes and business expansion. It enables you to handle business growth efficiently without compromising quality or customer service.

Enhanced regulatory compliance

The software simplifies audit preparation and execution, ensuring industrial regulatory compliance. It complies with traceability requirements for quick identification of products in case of product recalls.

How does Water Delivery Solutions help?

Water Delivery Solutions is a cloud-based solution built on an extensive ERP platform that provides end-to-end solutions for bottled water manufacturing businesses. This ERP software streamlines processing from material requirement planning to batch tracking, sizing, and scaling. Contact us to learn how we work and see how we can help your bottled water business.

He loves to explore. His passion for helping delivery industries in all aspects flows through in the vision he has. In addition to providing smart solution to make delivery process flawless, Ravi also likes to write sometimes to make it easier for people from business industry looking for digital solutions.